Mastering Construction Site Safety with Effective Walkarounds

Without proper safety precautions, the construction industry may be one of the most dangerous places to work. According to OSHA, almost 20% of worker fatalities in 2019 happened in the construction sector. While inspections and audits can improve the safety standards on a construction site, regular safety walkarounds can significantly reduce the likelihood of accidents.

They’re also essential and mandatory in the construction industry; according to many laws, operators are required to conduct a walkaround before using certain equipment and tools.

In this article, we explore the importance of a safety walkaround in construction sites as well as some of the best practices for conducting effective walkarounds.

What is the importance of a safety walkaround on a construction site?

A safety walkaround is a process used to ensure that all the necessary safety protocols are followed in a workplace. The process is similar to an inspection or an audit but is much less formal compared to them.

Unlike an inspection or an audit, a walkaround is usually conducted by the organization’s employees and the goal is not to find regulatory violations but to improve the safety conditions in the organization. The process is also more informal and if possible the safety issues are rectified during the walkaround itself.

Even if an organization tries to follow all the safety precautions and protocols, sometimes employees simply slip up; maybe they forget to wear their protective gear, maybe spills and leakages may create an unsafe environment, or maybe exposed wires may create the risk of electrocution. These incidents may happen even in organizations that otherwise follow the best safety practices.

This is what a safety walkaround aims to prevent. Inspections and audits are resource intensive and can even affect productivity and therefore cannot be conducted daily or more often. But with an effective safety walkaround, an organization can significantly reduce its safety risk without using more resources.

Walkarounds also build a culture of safety within the organization and reduce safety-related expenses. While classes and seminars on safety can help employees learn various protocols and safe operating procedures, it’s difficult to actually implement them. But when you’re regularly checking up on these standards, the employees are more motivated to put them into practice.

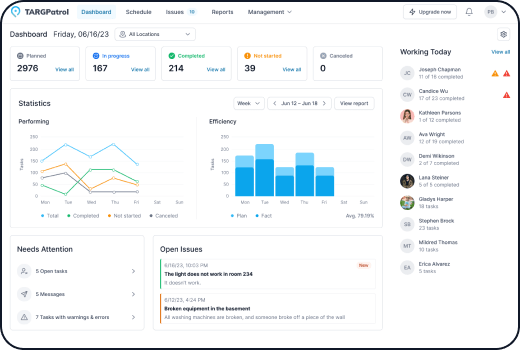

Organizations can also check up on the construction equipment during these walkarounds. With daily monitoring, you can keep track of equipment status and make sure it’s in optimum condition. The team can also make sure the equipment gets the maintenance at the right time. With tools like TargPatrol, walkaround teams can log in equipment conditions and analyze them for planning and coordinating maintenance activities.

What do you need to look out for during a safety walkaround on a construction site?

Some of the common violations found during OSHA inspections in construction sites are:

- Fall protection and fall protection training

- Improper use of ladders and scaffolding

- Eye and face protection

So it’s important to include these aspects in safety walkarounds.

Make sure that all workers have adequate safety equipment and that they are worn correctly. Ensure that equipment that involves disposables such as face masks, air filters, etc are replaced in regular intervals and are not outdated.

Check the safety of the construction equipment they’re using. Make sure that workers are not at risk of failure of equipment, particularly the ones that carry heavy loads or are under tension. If there is electrical equipment on site, check for frayed wires, wet surfaces, overloads, improper circuit breakers, etc.

It’s also essential that the workers are provided with the right equipment for the work; if they’re lifting heavy loads manually or with equipment not rated for the loads it may cause injury or damage to the equipment. If there are loud noises in the workplace, check to see if everyone is wearing hearing protection.

You’ll also need to control the access to the construction site. Make sure that only authorized personnel are entering the premises. If there are any visitors to the site, make sure they’re wearing protective equipment and are accompanied by a professional at all times.

Another aspect is access to the workplace. Make sure workers can easily reach the workplace without falling or slipping hazards. Verify that the areas under construction or that present a danger to workers are clearly marked. Check for any equipment out of place or in the way posing a danger to the workers. If there is any scaffolding, make sure they’re inspected to make sure they’re sturdy; if not rectify it immediately. If any excavation work is performed, make sure that the location is stable and is marked clearly.

If any vehicles are used in the workplace, ensure they’re in proper working conditions and are operated only by licensed and trained professionals. Ensure that these vehicles get a walkaround inspection before they’re operated. Check for maintenance logs and ensure they’re getting regular maintenance.

You can use the TargPatrol app to mark any issues that you found during the walkaround. Admins can configure different types of issues, based on priority or impact.

What are some of the best practices for safety walkarounds?

1. Conduct regular walkarounds

For effective walkarounds, you need to conduct them regularly. With regular walkarounds, you’ll be able to find recurring issues and fix them in the long run. You’ll also be able to keep track of the equipment at the site, monitor their conditions, and plan maintenance and repair.

2. Use checklists

Checklists help maintain the standard of walkarounds. They ensure that all safety points are covered and keep a log of the same. Admins of the walkaround team can create checklists and schedules and assign them to team members through the TargPatrol app. The team members can check off the tasks as they complete them. The logs can later be used during audits or inspections.

3. Log all details

Make sure any and all issues are logged by the safety personnel. The personnel must be trained to log issues even if they’re rectified on the spot. It’s also a good idea to tag and label different types of issues so that the relevant teams can easily prioritize them. Logs will also help analyze issues at a later stage to find recurring problems.

4. Monitor equipment conditions

While conducting walkarounds, log the conditions of all the equipment on the construction site. Detailed logs can help keep track of wear and tear on equipment and schedule maintenance accordingly. It can also prevent safety issues; worn-out equipment can pose a safety risk for operators and other workers on the construction site. By keeping track of them, you can ensure that the machinery gets repaired on time and that it doesn’t fail unexpectedly costing you in terms of unplanned downtime.

5. Track and monitor the walkaround teams

Walkarounds themselves can present safety risks, even with the best safety precautions. The personnel is actively looking for unsafe situations and it’s important to ensure they get quick assistance if they’re in trouble. For this, you can use GPS or RFID systems to keep track of your employees. RFID or NFC tags placed along the walkaround route may be a better solution since GPS won’t be able to tell what floor the people are at. These tags can also be used to make sure that the team covers all the checkpoints and to keep extensive logs.

6. Automate as much as possible

While you cannot automate the walkaround itself, you can automate some of the tasks. For example, you can set automatic alerts for employees for their walkarounds. You can also trigger workflows and work orders in case equipment conditions exceed the parameters. Using TargPatrol, you can automatically track the employees when they conduct the inspections and even automatically check off tasks. With automation, you can ensure that all the tasks are followed and reduce the workload for your team.

7. Ensure regulatory compliance during walkarounds

While planning the walkaround and preparing the checklist, it’s important to take into account the regulatory requirements as well. There are plenty of safety requirements around a construction site, the different types of equipment used, the vehicles that may be present at the site, the protective gear used, etc. Make sure to check that the construction site is compliant to these regulations and that they’re clearly logged.

8. Make sure you’re wearing proper PPE

A construction site is a dangerous place to be in and it must be ensured that all personnel, including the ones tasked with the walkarounds, are wearing personnel protective equipment.

9. Analyze the results and make continuous improvements

To get the best results out of the walkarounds, make sure that you analyze the safety and maintenance logs. You can use this data to make safety improvements and better manage your maintenance strategy.

Read more: Darby Mine No. 1 disaster