Identifying Key Hazards: Preventing Accidents on Construction Sites

The construction industry is one of the most dangerous work environments in the US and across the world. While the workers in the industry comprise only 6% of the total working population, 10% of workplace-related fatalities happen on construction sites. While there are strict regulations for workplace safety, accidents still happen due to safety overlaps and cause injuries and fatalities.

In some cases, construction companies take cost-cutting measures, often at the cost of worker safety. In some instances, the workers put themselves in danger by ignoring safety precautions for convenience.

Either way, the first step in preventing injuries and accidents is to identify what causes them. Let’s have a look at some of the common causes of accidents and injuries at construction sites.

What are the common causes of accidents on construction sites?

1. Falls

Falls are the top cause of accidents in the construction industry. In 2019, it was responsible for 36.4% of all fatalities in construction. It’s one of the ‘focus four’ - the four types of accidents that are most common.

Falls are often caused by slippery surfaces, as well as a lack of adequate protection and training while working at heights. They can cause severe injuries, and if from a sufficient height, even death of workers.

Even though its common knowledge that falls are one of the common causes of accidents and deaths, data indicates that most companies and managers don’t often give it enough importance. Lack of sufficient fall protection and training to prevent falls are two of the top ten common OSHA violations in the workplace.

2. Struck by objects

Injuries by being struck by objects are another one of the focus four in the construction industry.

Construction sites often have a lot of movement; both workers and equipment are constantly moving to transport construction materials and machinery. Without sufficient protection, workers can be struck by these objects and can be severely injured.

Nail guns are one of the common causes of these incidents. Without proper training and precautions, operators or other workers in the vicinity may get struck by nails and get seriously injured.

Another common cause for these accidents is cranes and other rigging equipment. Accidents happen when workers or operators are not aware of their surroundings or enter their area of operation without proper precautions.

Sufficient PPE protection and a well-trained workforce can limit injuries from being struck by objects in the workplace.

3. Caught in between

The difference between injuries from being struck by objects and from being caught-in-between objects is that in the former, the injuries are from the impact alone, while in the latter, it is from impact and crushing force as well. Caught-in-between injuries include those from cave-ins, being pulled into or caught in machinery, and being crushed in between moving and stationary parts of a vehicle or other machinery.

Such accidents can cause anything from minor scrapes to amputations or even death.

These accidents commonly occur when workers aren’t properly trained to handle the equipment and are not aware of the risks. Around 5.4% of all fatal workplace injuries were due to being caught in-between objects or machinery.

4. Electrocution

Electrocution was the third leading cause of fatalities in the construction industry during 2018 - 2019. Injuries from electricity aren’t limited to an electric current directly passing through the body. It can be from an arc flash which can cause serious burns, from a fire due to faulty wiring or other electrical issues, or even an explosion triggered by an electric current.

Electrocution can occur from faulty equipment, accidental contact with power lines, and improper use of extension cords or cables. It can cause serious burns and death. In some cases, the worker may sustain other physical injuries if they fall or get struck by objects as a result of electrocution.

5. Repetitive stress injuries

Unlike other accidents, repetitive stress injuries rarely occur from one incident. They develop over time when the worker is exposed to unsafe working conditions. There are over a hundred types of repetitive stress injuries, with carpel tunnel syndrome being one of the most well-known.

As the name suggests, they’re caused by repeated stress to body parts, often due to the same motions during work or from using power tools over extended periods of time. Poorly designed equipment, staying in the same position for long durations, using vibrating equipment, and many other factors can contribute to a repetitive stress injury.

6. Ladder-related accidents

Improper use and construction of ladders are among the most commonly found OSHA violations.

In most cases, ladder-related accidents are due to improperly placed ladders. Placing the ladder on unstable ground or on top of barrels or boxes can cause them to slip and cause serious injury to the worker. Ladders also have defined load ratings, beyond which they may break or bend and cause injuries.

In the case of wooden ladders often made at job sites, workers may injure themselves on sharp edges or protruding nails.

7. Scaffolding-related accidents

Scaffoldings are commonly used for the construction and maintenance of buildings and are a common sight. The most common type of scaffolding is built alongside a construction, but even platforms suspended from the top of a building and scissor or aerial lifts are considered scaffoldings.

While they’re an integral part of the construction industry, they’re also a common cause of accidents. Improperly constructed scaffoldings won’t be able to handle the expected load and can fall over or break up. They can also be damaged by falling equipment or heavy loads, which can put the workers at risk.

8. Accidents due to power tools

Construction sites often use a lot of power tools for shaping up the materials and joining different components. Without proper training and protection, these tools can cause serious injury and even death. Workers may get their limbs into rotating components of this equipment, and in some cases, the material they’re working on may fly off and hit them.

Power tools using pressured air or electricity can injure the operators or other workers in proximity. They also present a risk of electrocution and even fire if not handled with care.

9. Vehicle-related accidents

Construction sites, in general, have some amount of vehicle activity, often to bring in or move materials. In some cases, these vehicles are directly involved in construction, as in the case of cranes, vehicles used for road construction, and others.

These vehicles pose significant safety risks to the workers on the site. Without proper training and precaution, they can injure or even kill workers. In the case of construction sites near roadways, workers are also at risk from vehicles that pass by.

10. Fires and explosions

Fires present a safety risk in almost all construction sites. Explosions are much less common and are often limited to sites of demolition. They both present serious risks to workers.

Almost all construction sites use flammable materials, from wood to paint and varnishes. Even fuel from vehicles used in construction can present a fire risk.

In industries that make use of explosive substances, a lack of proper care and precautions can cause serious accidents.

What are some of the steps you can take to prevent accidents in a construction site?

1. Provide regular training

Regular training can significantly reduce accidents in the workplace. If we look into incident reports at construction sites, we can find that most accidents come down to a lack of training or expertise.

Employees should be trained in proper safety procedures at the site - when they join and then at regular intervals. They should be able to navigate the construction site and perform their duties without taking huge risks. Workers should have adequate training on using personnel protective equipment whenever necessary. If they’re using any machinery, they should be properly trained to do so.

Employees must also be regularly trained in emergency procedures and first aid.

2. Conduct regular tests and walkarounds on the equipment and machinery

Equipment failure can have disastrous effects on employee safety. If the protective gear isn’t in proper working condition, employees may have a false sense of safety which can put them in danger. If the machinery that the employees are not in a safe condition, employees may be injured or worse. Faulty equipment can cause fires, drop heavy loads unexpectedly, and can put the operators and workers nearby at high risk.

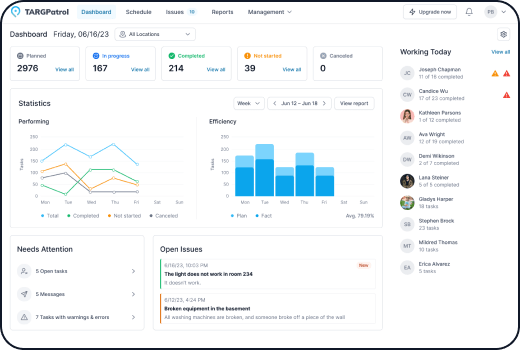

But with regular inspections and walkarounds, organizations can ensure that the equipment is fit for use and ensure timely maintenance. With tools TargPatrol, companies can radically improve equipment safety and reduce maintenance costs through regular walkarounds.

3. Inspect the working conditions regularly

Even if organizations train their employees and use safety precautions, it can erode over time. Workers and managers may override safety precautions and rules for convenience and put themselves in danger.

But by monitoring the working conditions regularly, you can make sure that the environment is safe and that proper safety protocols are followed. You can also make quick corrections before problems build up and cause accidents. It may be a good idea to set up a checklist and go through it regularly to ensure that the inspection team doesn’t miss or forget anything.

Tools like TargPatrol can help you conduct effective inspections and walkarounds. With TargPatrol, you can make detailed logs about your safety protocols in the event of inspections from any regulatory authorities.

4. Build a safety culture

Safety rules and regulations can reduce the likelihood of accidents. But these often come from regulatory authorities, company management, and safety officers. Employees may not be aware of the safety risks, and over time there may be lapses in safety.

In building a safety culture, the initiatives come from the workers themselves. They’re aware of the safety risks and the importance of following the correct procedures. Even with little supervision, the employees will stick to the rules and won’t become complacent over time.

5. Provide protective equipment

Protective equipment is essential for employees at a construction site. Almost all construction sites require hard hats to protect workers from falling objects. If there is overnight construction, workers must be provided with adequate lighting and clothing that makes them visible.

If heavy machinery or power tools are involved, the operators must be provided with equipment to keep them safe from strong forces, electrical shocks, flying debris, and other elements that can harm them.

6. Conduct regular safety audits and meetings

Regular safety meeting help identify issues quickly and rectify them before it causes an accident. The data from the daily walkarounds and inspections can help organizations spot recurring issues. They can use this to create further awareness among the workforce about the risks. Organizations can also use safety meetings to train their employees on the latest safety protocols.

While regular safety walkarounds can help, it’s a good idea to have an external auditor inspect the working conditions every once in a while. They can help you identify areas that your team may have missed and give a safety boost to your organization.

7. Maintain a clutter-free workplace

A cluttered workspace is not only unsafe, but it also reduces productivity. Employees will have to spend time looking for equipment and material instead of moving the project along in a cluttered working environment.

If there is equipment or material lying around the workplace, it can cause a tripping hazard. Workers can also get injured from powertools lying around connected to a power source.

Make sure that the construction site has designated spaces for storing materials safely. There should be mechanisms in place to remove any waste from the construction space. Employees must be trained to store equipment and machinery safely when not in use.

8. Ensure workers take proper breaks and are well rested

Worker fatigue can cause a lot of accidents. Tired or sleepy workers can be distracted and may not follow proper safety protocols.

Workers who remain in the same position for a long time can also be prone to repetitive stress injuries. Working in high ambient temperatures can make workers dehydrated and make them prone to heat strokes.

Make sure that the workers are getting adequate rest and are taking enough breaks. Ensure that they’re properly hydrated and that they have their food on time.

Try TargPatrol to improve safety at your workplace

TargPatrol is one of the easy tools you can implement at your construction site, guaranteed to improve safety. With TargPatrol, your organization can conduct better inspections and walkarounds with the least effort. The tool can help you automate safety to a large extent and ensure strict standards at a construction site. Check it out now, and keep your workers safe with little effort.

Read more: How to organize walkarounds in construction sites?