What should you look for in a CMMS?

Key Considerations for Choosing the Right CMMS for Your Operations

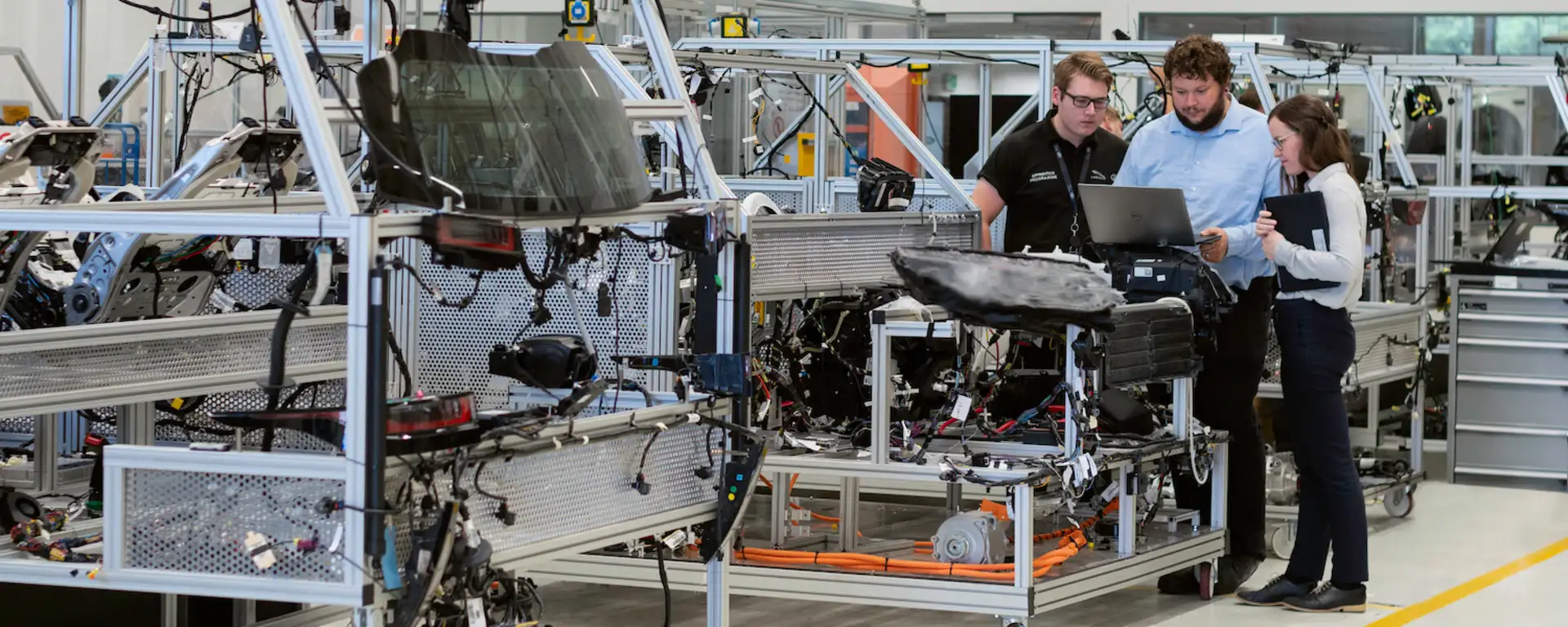

Maintenance and repair of assets are one of the main operational costs for organizations, particularly in the manufacturing and assembling industries. In 2020, 46.91% of companies in North America reported that they spent 21% to 40% of their operational budget on maintenance and cleaning. In 2021, the global maintenance and repair market was valued at USD 254.04 billion and is expected to grow at a CAGR of 2.25%.

With this significant chunk of resources being allocated purely for maintenance, companies have been exploring solutions to streamline their repair and upkeep processes. And one of the popular solutions is a CMMS or a Computerized Maintenance Management System.

What is a CMMS?

A computerized Maintenance Management System or a CMMS is a software used to streamline the maintenance and repair activities in an organization. The solution keeps track of all the equipment and assets in an organization as well as their maintenance status and makes them easily available to maintenance teams. The software is also referred to as a Computerized Maintenance Management Information System or CMMIS.

CMMS is commonly used in industries that use a lot of equipment and machinery such as manufacturing and assembly, oil and gas, automobile industry, construction, and others. In its simplest form, a CMMS is a database that keeps maintenance information for all the equipment. It is used to store information regarding when the next maintenance is due, the spare parts available, a log of all the maintenance and repair activities performed, and everything a technician may need to repair or refurbish a device.

Modern CMMS systems integrate with other software solutions that organizations use, such as ERP, asset and inventory management, etc. They have multiple access roles, let you set maintenance schedules, assign tasks to personnel, check their progress, and keep track of equipment conditions regularly. It also sends notifications to the relevant parties when maintenance is due on any machinery.

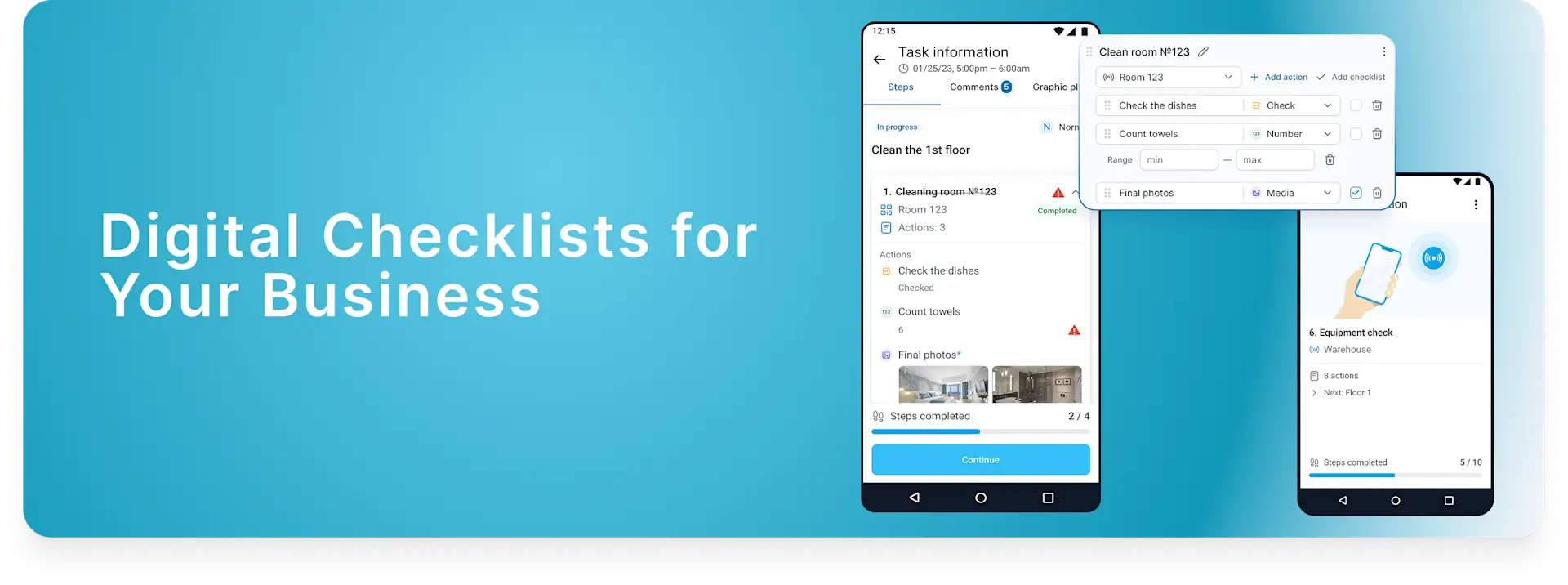

CMMS systems also often have mobile apps; admin teams can access all the maintenance information through the app and maintenance personnel can easily log in to relevant information. For example, if someone is fixing a machine that broke down and wants to log in specific information about it, they can easily do so through the app. They can also add photographs showcasing a damaged component or any other parts that may be relevant to the admin team. For example, with the TargPatrol app, employees can take photographs, label incidents, and log information about the equipment's condition.

Many companies often use QR codes or NFC or RFID tags to identify equipment and keep track of them. And with many CMMS systems, technicians can pull up all the information about a piece of equipment including its repair history just by scanning this tag.

What are the benefits of using a Computerized Maintenance Management System?

✅ CMMIS streamlines maintenance activities

At its core, this is what a CMMS system does. Without a CMMS system, organizations with a large set of assets will find it difficult to manage their maintenance and repair activities. Employees will have to manually keep track of maintenance schedules and logs. Repair teams will have a tough time managing the resources; work orders and supplies may go all over the place and maintenance activities may be delayed unnecessarily.

✅ CMMS improves transparency and decision-making in organizations

A computerized maintenance management system offers a clear view into the state of equipment in an organization. It helps organizations to quickly get a list of equipment that may need replacement, the spare parts they need to stock, and the equipment that is failing frequently, and use this information to plan their budget. It helps organizations understand the state of maintenance and repair in the organization and make decisions accordingly.

✅ Reduce maintenance costs

Using a CMMS and keeping track of the equipment conditions, organizations can optimize their maintenance schedules. They can reduce unnecessary expenditure on preventive maintenance by predicting when a piece of equipment may need maintenance.

✅ Simplify the workload for employees

CMMS makes all maintenance-related information easily available and accessible. It makes it easy for employees to quickly find the information they need and at the same time keep logs of the work they’re doing. Without a CMMS, technicians will find it difficult to keep track of the maintenance status of different equipment, locate spare parts, or communicate issues from operators to repair personnel. Maintenance management simplifies this for the whole team.

✅ Reduces asset management costs

With the data from a CMMIS system, an organization can weigh the pros and cons of preventive maintenance and reactive maintenance. They can evaluate the ideal strategy for individual pieces of equipment by accurately measuring the costs associated. CMMIS also ensures that maintenance is not missed by alerting the personnel; by repairing and maintaining equipment regularly, they are likely to last longer without loss of performance.

✅ Prevent downtime

Unexpected equipment downtime is always costly to the organization; the production process may be halted, productivity is lost, and deliveries may be delayed. With a computerized maintenance management system and equipment condition monitoring, organizations can predict when machines need equipment or are reaching their end of life. It helps organizations prevent downtimes, and if unavoidable, plan it and schedule them for minimum disruption.

What are the features you should look for while investing in a CMMS?

A CMMS needs a good analytics suite

A computerized maintenance management system should help the organization reduce its expenses related to maintenance. And for this, the system should let users analyze how often different equipment fail, the cost associated with their maintenance and replacement, and empower organizations to develop efficient maintenance strategies. The solution should also be able to generate reports showcasing the data.

Complete asset management

The solution should be able to store information related to all the different types of assets. Technicians should be able to log and access maintenance logs as well as check the inventory for spare parts and components. Employees should be able to check the availability and check out the equipment they may need. The solution must be able to keep track of different equipment - where they are, who is in charge of it, if it is functional, if it needs repair, etc.

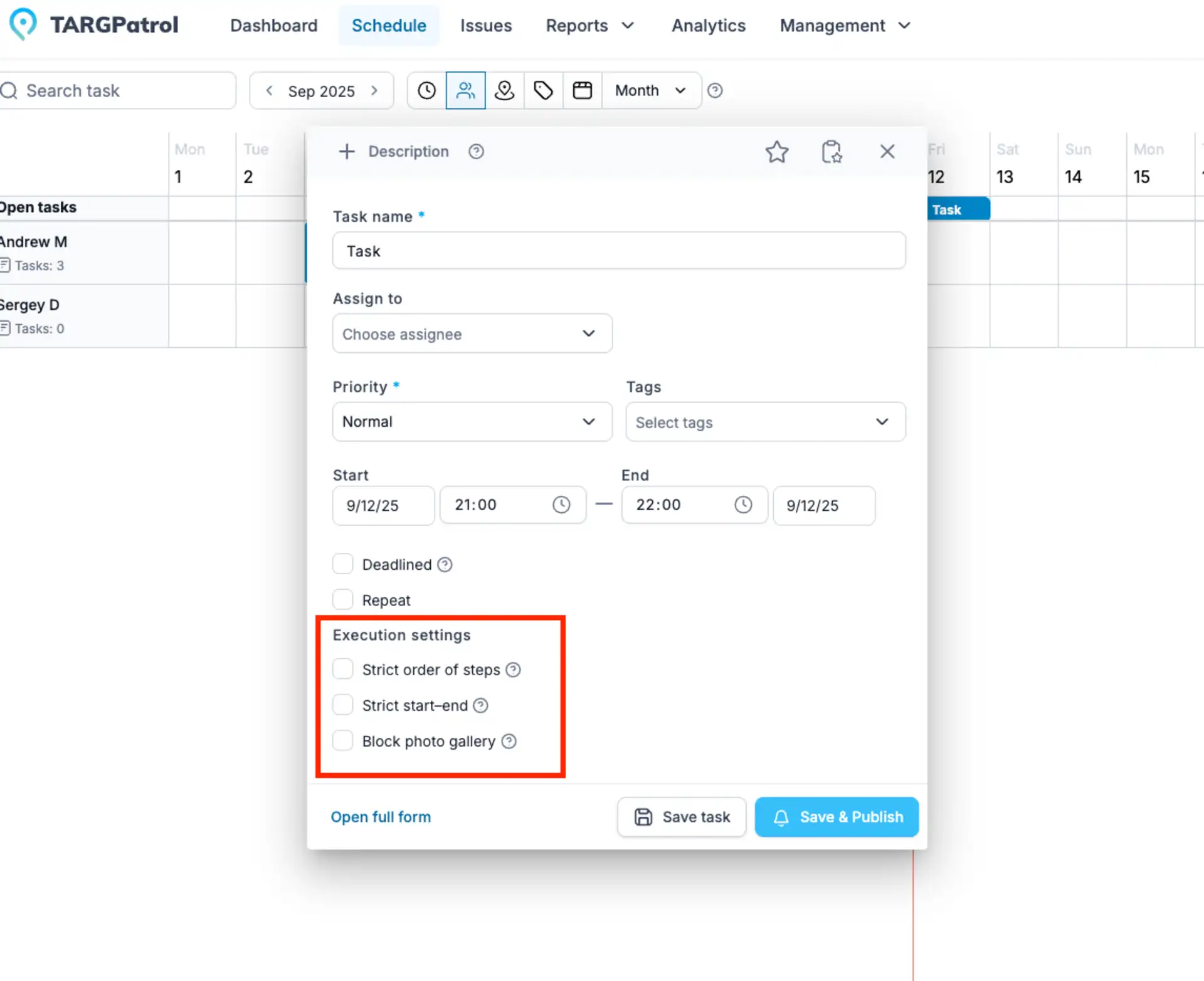

Work order management

Authorized personnel - operators of equipment, managers, and other employees - must be able to request equipment repair through the CMMS. The solution should have customizable templates and workflows for creating work orders, getting the approvals, and completing the repairs. In the case of preventive maintenance, it must be possible for the admin team to schedule maintenance and automatically create work orders. In TargPatrol, the admin team can set up work schedules, assign them to different team members, and log the information once the maintenance is completed.

Keep track of maintenance personnel and make sure all tasks are completed

When there are too much equipment to take care of and too many maintenance tasks to be completed, some may be missed out. And in some cases when the equipment is safety critical, you’ll need logs of maintenance activities as you simply cannot afford to miss them. So your CMMS must be able to keep track of their employees, either through GPS, NFC, or RFID tags, and automatically log the activities.

Best practices while using a CMMS

1. Update it regularly

An out-of-date CMMS is as good as having no CMMS. Your employees and the maintenance team need the latest equipment and maintenance data to carry out their tasks efficiently and effectively. Without updated information, you may miss out on maintenance or carry out unnecessary maintenance activities. Train your technicians and employees to log equipment information regularly and to check the log before conducting any maintenance activities.

2. Create a data-to-action pipeline

A CMMS can help organizations reduce their cost of maintenance and repair. By analyzing the maintenance logs and equipment conditions, organizations can optimize their processes, improve the lifespan of their equipment, reduce equipment downtime, and create more value from their equipment. But for this, organizations need to set up mechanisms in place to collect the data, analyze it to find insights, make sure the insights reach the right people, and that the right people make data-centered decisions.

3. Reduce cognitive overload for the end user

For a CMMS to be successful, your employees and maintenance crew have to adopt it. They have to request maintenance through it, schedule related activities and update it regularly. For this, the user experience is very important. If it takes too long to request maintenance or if a task is being held up because the technician is not able to access the relevant information, your team will revert back to their earlier mode of working. For high adoption rates, you need to engage with the users, collect their feedback, and make sure that the CMMS is not slowing things down for your team.

4. Automate as much as possible

Modern CMMS solutions offer a lot of automation such as creating work orders and triggering workflows. TargPatrol lets organizations automatically track their team and mark activities performed. Automation ensures that all the tasks are completed well and that there are no missing activities. It also reduces the workload for the team; it makes CMMIS a tool that simplifies things instead of adding on more work.

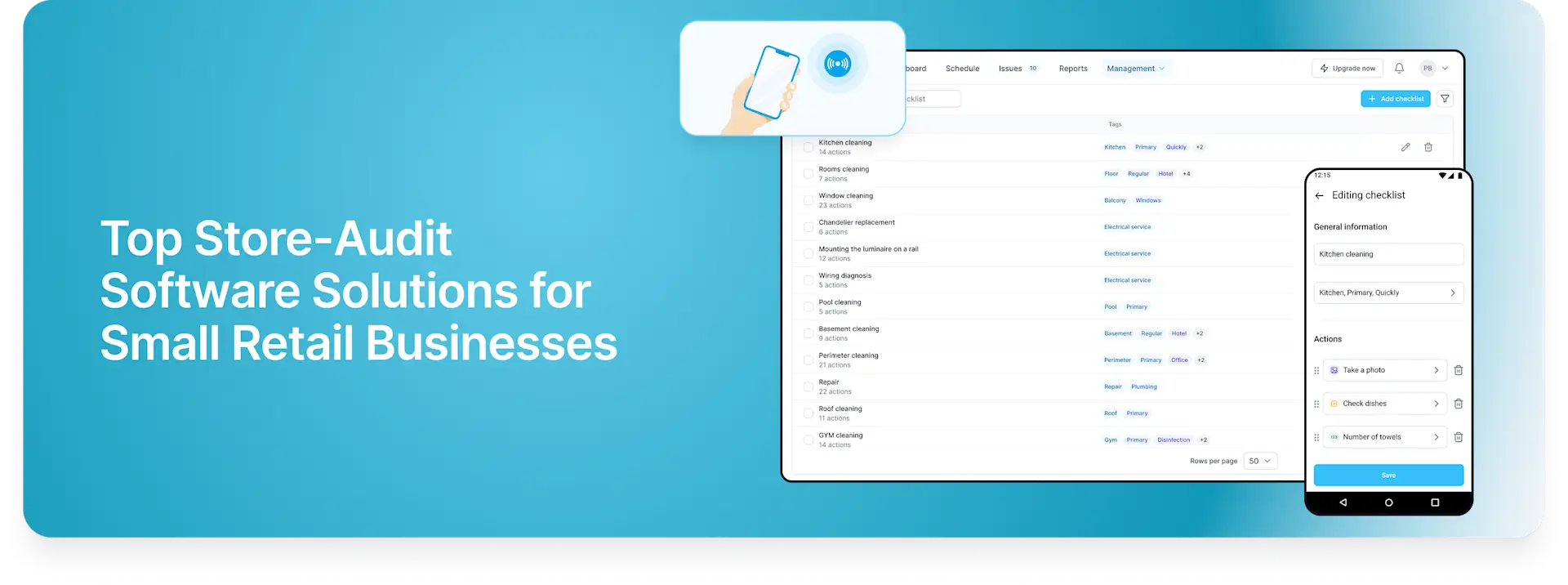

5. Create templates for different types of repairs and equipment

Checklists and templates ensure that all the tasks are carried out well. Templates standardize processes; for example, if someone requires maintenance of specific equipment, a request form ensures that the technicians have all the information they need to diagnose the problem and fix it. They also make sure that organizations don’t miss out on tasks; for example when logging in maintenance details, workers may not remember to add all the necessary information. A custom-designed form standardizes this and ensures that all maintenance logs follow a standard and are easy to understand.

6. Don’t forget the people

People make or break initiatives. As discussed earlier, the adoption rate is an important metric that showcases the success of a CMMS. Make sure that all the employees and technicians are aware of the system and make use of it. It’s also important to get buy-in from executives in the management; their participation will emphasize the importance of the solution among employees and improve the adoption rates. Make sure you involve all employees during every stage of implementing a CMMIS in your organization.